National Science Foundation funds two-year study of Behrend engineering teams

Engineering may seem to be a solitary endeavor, with professionals spending hours in the lab thinking, analyzing, and problem-solving. The reality is that it is a highly collaborative field; most engineers are part of larger teams, often interdisciplinary, working to accomplish common goals.

Recognizing the importance of teamwork in engineering, the National Science Foundation has funded a two-year, $200,000 study of group dynamics and collaborative problem-solving in simulated manufacturing environments at Penn State Behrend. Faculty members from two schools of the college will oversee the research, which will assess innovation, creativity, and metacognitive awareness—a mindfulness in how one approaches work—among teams of engineers.

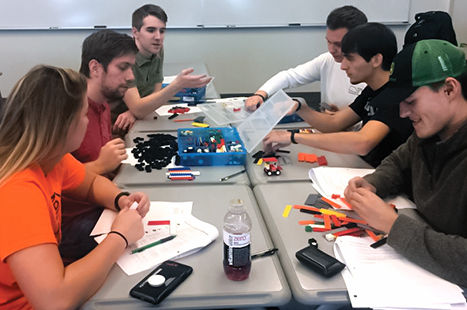

In the study, engineering students will work in teams to complete manufacturing simulations, using blocks to construct LEGO cars. Students will work individually in physical and virtual-reality (VR) simulations, each learning a different aspect of the assembly process. Then, in groups, they will try to make the process faster and less expensive by reassessing the design, sourcing, manufacturing, and inspection of the toy-block cars.

“Team members may have different opinions about how best to do that,” said Faisal Aqlan, assistant professor of industrial engineering, who will oversee the manufacturing simulations, “and they might all be right. The goal of the project is not to build a cheaper toy car. Instead, we hope to identify any shortcomings in our students’ professional skills — the ability to communicate, to work in a team, and to resolve conflicts.”

The design of the study, which includes faculty members from both the School of Engineering and School of Humanities and Social Sciences, is itself an exercise in teamwork.

“Our engineering students tend to think in a linear process,” said Heather Lum, assistant professor of psychology and a co-researcher on the NSF study. “That’s how we present content in their courses: ‘You need A, B, and C to get to the end goal.’

“That’s fine when we’re teaching a black-and-white technical skill,” Lum added, “but there are gray areas, particularly when you work in a group setting, that sometimes require you to think in a deeper, more critical way.”

Lum’s role in the NSF project will be to test the students in VR environments. An eye-tracking system embedded in the VR headsets will allow researchers to note which LEGO blocks students look at, and for how long, as they select materials for the manufacturing process.

The VR simulations also can be used to anticipate conflicts when students advance to a team environment. If one student is tasked with building the lightest car possible, for example, and another is tasked with minimizing the cost of the car, their goals might align —but also could require compromise as materials and processes are selected.

Richard Zhao, assistant professor of computer science and software engineering, will lead the development of the VR environments, using the Unity game engine and the HTC Vive VR headset. An additional $37,000 from the National Science Foundation will support that work, which also will involve a team of undergraduate student developers.

Lisa Jo Elliott, assistant teaching professor of psychology, will build analytical models to measure the students’ alertness in different environments.

For the physical simulations, Aqlan will adapt LEGO-kit assembly projects from a three-year Research Experiences for Teachers study of manufacturing systems. That study, which also was funded by the National Science Foundation, produced simulations for a variety of manufacturing approaches, including craft production, mass production, lean production, mass customization, and personalized production.

In the new study, researchers will develop VR simulations for each of those five manufacturing approaches. They will then assess the differences in student learning in both the physical and VR environments. By studying the dynamics of each group — particularly the challenges when students have to work collaboratively to solve a problem — Aqlan and the other researchers hope to develop a decision-support protocol for the teams. That could be useful across engineering curriculums, and in disciplines beyond the School of Engineering.

“Our goal is to come up with an intervention that will remove the most common conflicts and errors,” Aqlan said. “If it’s the design that’s a problem, you change the design. If it’s the process, you change the process. If the problem is related to the people in your team, however, your options may be more limited. You can’t always form a new team. That’s why those professional skills are so essential today. You have to be able to communicate, collaborate, and find ways to move the team forward.”