Prischak Robotics and Automation Lab opens in Burke Center

Although it's been open only since late last year, the new Prischak Robotics and Automation Lab in the School of Engineering is drawing the attention of area manufacturers and businesses that want to collaborate with Behrend on research and development projects.

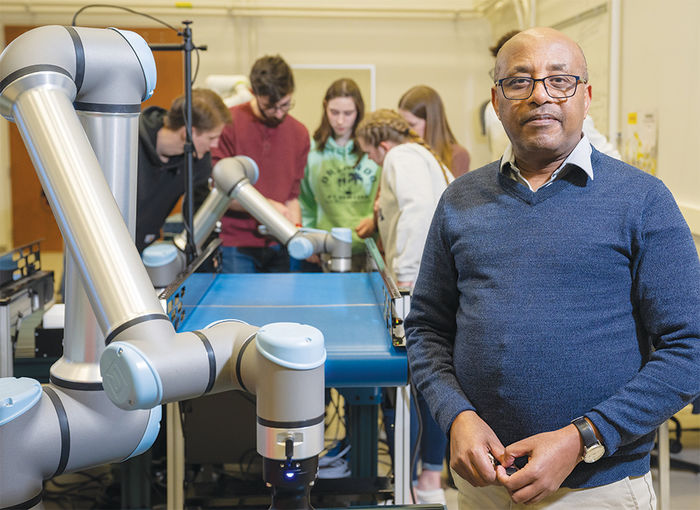

It's no surprise to Dr. Yohannes Haile, assistant teaching professor of management and industrial engineering, who points out that every manufacturer has a goal of improving their processes and/or production.

"Robotics and automation make manufacturers more competitive by increasing efficiency, lowering labor costs, and reducing the ergonomic stress on workers," Haile said.

Robotics and automation can also help with labor shortages.

"Current estimates indicate there are 500,000 open manufacturing jobs in the country right now," he said. "That is estimated to grow to 2.4 million by 2028."

Haile has already had discussions and visits with regional manufacturers such as Parker LORD, Cummins Jamestown Engine Plant, Lake Erie Rubber, Port Erie Plastics, PC Systems of Ridgway, and the Plastek Group to explore potential projects. This summer, Penn State's Board of Trustees toured the facility as well.

The lab is equipped with a range of cutting-edge equipment, including four industry-grade collaborative robots, vision systems, sensors, and controls used in manufacturing. A FARO® laser scanning arm will be installed soon.

The facility was made possible by a $1.2 million gift from Erie-based plastics packaging manufacturer Plastek Group and the family of its founder, the late Joe Prischak.

"The lab is configured to be both internal and external facing," Haile said. "The internal facing aspect advances experiential learning by students and supports the college's research activities, and the external facing aspect supports collaboration with industry, providing a safe sandbox for innovation and experimentation of new ideas and concepts away from the manufacturing floor and also serving as a resource for upskilling of a company's workforce."

Beyond providing industry support, the foremost goal of the lab is to give students opportunities to gain hands-on experience in robotics and automation through research projects, internships, and co-op programs. Several students work in the lab as research assistants, and a visit to the lab is incorporated in many engineering classes in the various disciplines, as nearly all engineering students can be expected to work with robotics in some form in their future careers.