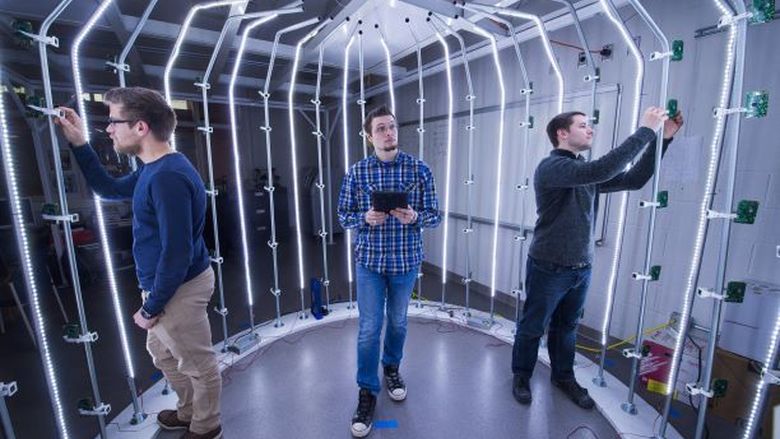

Three students who worked in Penn State Behrend's Innovation Commons lab have launched their own companies. John Nowakowski, front left, co-founded Bayfront Glass. Michael Gibilterra, at rear in center, and Michael Paul, front right, co-founded M2 Additive Manufacturing.

John Nowakowski and Michael Paul arrived at Penn State Behrend with an entrepreneurial mindset. Their work in the college’s Innovation Commons, an open ideation and rapid-prototyping space, built on that, catapulting both toward businesses of their own.

“I’ve always wanted to own a business,” said Nowakowski, who earned a master’s degree in manufacturing management at Behrend. “That was always there, in the back of my mind.”

In the Innovation Commons, where he and Paul were student managers, Nowakowski saw firsthand the struggles that inventors and entrepreneurs face. The lab, which was the pilot site for the Northwest Pennsylvania Innovation Beehive Network, provides product design and development and other start-up services for innovators across the region, including students, who need help moving an idea forward.

The Innovation Commons received crucial early support from the Invent Penn State initiative and the Erie County Gaming Revenue Authority’s Ignite Erie collaboration. The lab has supported more than 180 projects, which have led to 10 start-up companies. Nine Behrend students have been named on patent applications related to their work there.

It’s no surprise, then, that Nowakowski and Paul started their own companies after graduation. Nowakowski is a partner in Bayfront Glass, LLC, a glass recycling company. Paul, who earned a degree in electrical engineering, partnered with Michael Gibilterra – a Behrend student who worked with him in the Innovation Commons – to launch M2 Additive Manufacturing, a 3D printing technology company that builds flexible 3D components.

Both men credit their early success to their experience at the Innovation Commons.

“One of the biggest takeaways for me was seeing the particular challenges that entrepreneurs didn’t expect to face,” Paul said. “There’s almost a pattern to the type of pitfalls that emerge. Because I had seen them again and again, my business partner and I were able to better prepare ourselves. We had a better idea of when to expect each challenge to present itself.”

Nowakowski learned the importance of persistence. When the entrepreneurs he worked with were ready to give up, he encouraged them to take a step back, reassess the situation and work to find a new solution. He has followed the same approach at Bayfront Glass.

“Developing a process or service is different from creating a widget, or an app,” he said, “but if you work with entrepreneurs enough, you notice that it doesn’t matter what the business is: If people have the spark, they’ll pursue it.”

Bayfront Glass hosted a series of pop-up glass recycling events throughout Erie County, collecting material and raising awareness about the company’s services. The initial response was positive, Nowakowski said. Changes in the international markets for waste material had upended municipal recycling operations, and several communities, including the City of Erie, no longer were accepting glass for recycling.

Another obstacle loomed, however: The company recently suspended its in-person collection of glass due to the COVID-19 pandemic.

Nowakowski is still looking toward the future. He hopes to one day open a full-scale glass recycling facility.

“Every time we did a recycling pop-up event, we saw the need for this,” he said. “Every time we talked to a container manufacturer, and we looked at their numbers, we saw a need for this. It’s just begging to work.

“We just have to stay the course,” he said. “There’s constant self-doubt, but I’ve learned that’s normal for entrepreneurs.”

Robb Frederick

Director of Strategic Communications, Penn State Behrend